Market Demand Analysis for Concrete Block Making Machines

In the ever-growing construction industry, the demand for durable and efficient building materials continues to rise. Concrete blocks are an essential component of modern construction projects, serving as a reliable and cost-effective solution for many building applications. To meet this demand, manufacturers have developed hydraulic press cement block machines that significantly enhance the production capacity and quality of concrete blocks. In this article, we will analyze the market demand for concrete block making machines, with a particular focus on hydraulic press cement block machines.

1. Growing Construction Industry:

The construction industry is experiencing robust growth worldwide, driven by urbanization, population growth, and infrastructure development. This expansion creates a steady demand for building materials, including concrete blocks. As regions continue to embark on ambitious construction projects, the need for efficient and productive concrete block making machines becomes imperative.

2. Shift Towards Hydraulic Press Cement Block Machines:

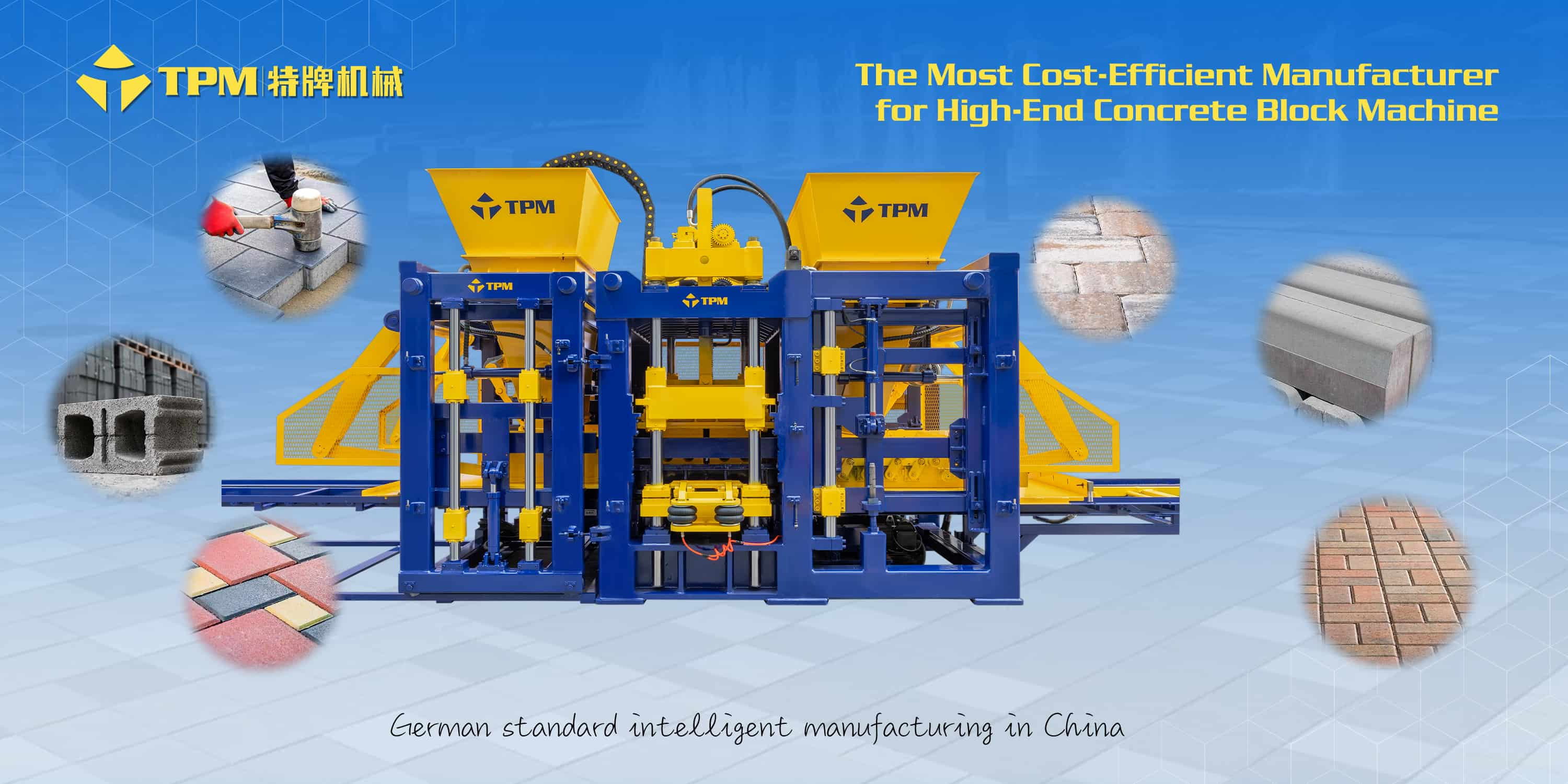

Traditional block making machines were often cumbersome and time-consuming. However, the introduction of hydraulic press cement block machines revolutionized the industry. These advanced brick block machines utilize hydraulic pressure to produce high-quality concrete blocks with precision and consistency. As a result, there is a noticeable shift in the market towards hydraulic press machines due to their superior performance and output.

3. Efficiency and Productivity Gain:

Hydraulic paver block machines offer increased efficiency and productivity compared to their manual or mechanical counterparts. These machines can produce a larger quantity of concrete blocks in a shorter period and with minimal manpower. The automated features of paving brick machines optimize the production process, reducing costs and improving overall profitability.

4. Consistent Quality and Customization:

One of the significant advantages of concrete cement block machines is their ability to consistently produce blocks of uniform quality. The hydraulic pressure ensures that each block is compacted properly, resulting in enhanced strength and durability. Moreover, these machines can be easily configured to produce blocks of various sizes, shapes, and designs, allowing manufacturers to cater to diverse customer requirements.

5. Environmental Considerations:

Sustainable construction practices are gaining momentum worldwide, and the use of sustainable building materials plays a vital role in this movement. Concrete blocks made by paving block machines are more eco-friendly compared to traditional methods of block production. These machines allow for efficient utilization of resources, minimize waste, and enable the recycling of construction debris, contributing to a greener construction industry.

Conclusion:

The market demand for concrete block making machines, is on the rise due to the growing construction industry's requirements for efficient, high-quality, and customizable building materials. The superior performance, increased efficiency, and consistent quality of blocks produced by hydraulic press machines make them an attractive choice for manufacturers. As the construction sector continues to flourish, investing in hydraulic press cement block machines can help meet market demands while improving productivity and profitability for businesses involved in concrete block production.

Links: TPM Bangladesh

Copyright 2025 @ Fujian Tepai Machinery Co., ltd. .All Rights Reserved.  Network Supported

Network Supported

Sitemap | Blog | XML | Privacy Policy