The TPM10000G is already known for its high-quality construction and reliable performance. But with our upgraded design, we have taken this machine to the next level.

One of the key upgrades is the use of a stronger and more durable frame. We have used the thickest square tube in the industry (200*200*10mm) and welded it with Japanese Panasonic pulse welding technology to ensure maximum strength and durability. The machine now weighs a solid 15 tons.

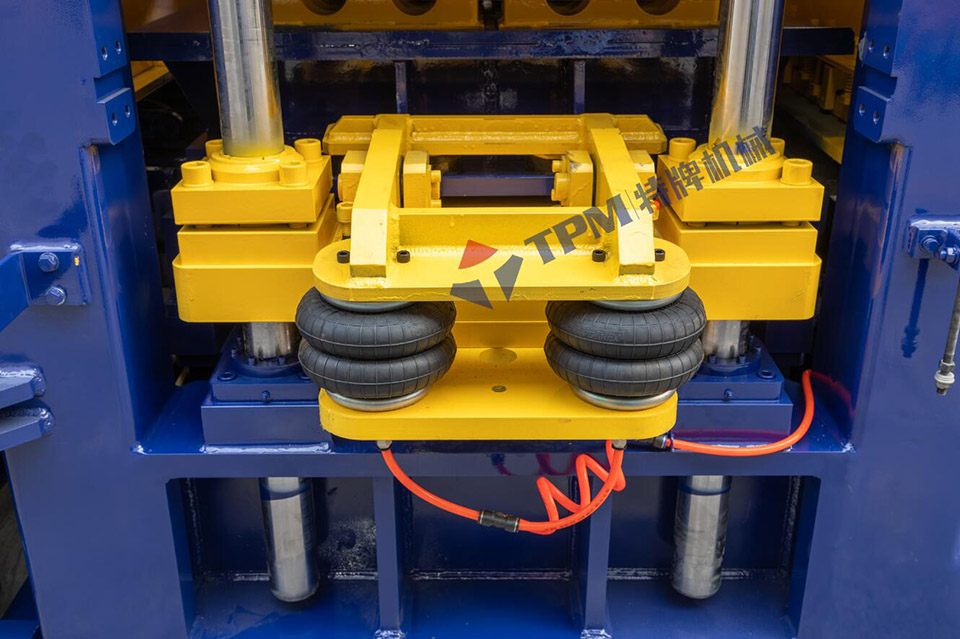

We have also upgraded the vibration system to an Italian servo vibration system. This system uses two 12.8kw servo motors to adjust the vibration force directly and achieve a maximum speed of 4500 rpm. This not only speeds up the molding process but also improves the density of the finished product.

Another upgrade is the use of a Siemens PLC control system. This system is more efficient and reliable than previous models, and it comes with a remote service system that allows us to diagnose and update the system in real-time.

We have also made improvements to the hydraulic system, using a 30kw Siemens hydraulic motor and high-quality Italian VTOZ hydraulic valves and American Albert oil pumps. This ensures that the hydraulic system is efficient and stable.

Other upgrades include a swing-type feeding system, a solid guide post with a graphene copper sleeve, and an inner frame stacking machine.

Overall, the upgraded design of the TPM10000G concrete block machine is a testament to our commitment to quality and innovation. We are confident that this machine will exceed your expectations and provide you with the best possible results.

Thank you for choosing TPM for your concrete block machine needs. We look forward to working with you and providing you with the highest quality products and services.

Network Supported

Network Supported